ARTICULATING BORESCOPES FOR POWER-GEN

The hatch pops open and Denise bounds over the last rung onto the top of a 300-foot tall wind turbine. Catching her breath she takes in the view of rippling green pastures dotted with turbines as far as the eye can see.After the strain of the climb, she smiles when she realizes how this view used to terrify her when she climbed up her first turbine. Now climbing 300 feet in the air is just part of her daily work routine. Denise is a wind turbine technician who just started her work day.

Her “office” is the top of wind turbines and her “commute” to work is climbing a ladder 300 feet in the air secured only by a system of lanyards, hooks, and harnesses.

After receiving reports that this particular turbine has problems with the rotational speed of the blades she immediately set out for the repair. Her main task for the day was to inspect the components, identify the problem, and repair the turbine before any more damage could occur.

Reviewing her checklist, she unwraps and wolfs down her her breakfast. Although she suspects the turbine’s gearbox to be the culprit she must also conduct routine inspections and oil changes for the rest of the components before ruling it out.

Denise stows away her unfinished breakfast and makes her way to the gearbox. Since it was the likely cause of the malfunctions, she decided to tackle this component first. The tool she brought with her for this particular component is an Articulating Video Borescope. Snaking the camera tip inside the gearbox, she begins her inspection.

A few minutes in, she spots the problem: a severely damaged high-speed shaft (HSS) bearing. She now knows exactly what she needs to do and dives right in.

THE INSPECTION

There are many components of a wind turbine that undergo regular maintenance and repair checks in order to keep the turbine fully functional and safe.

The main types of inspection techniques used for inspecting turbines are:

Drone

Oil Testing

Temperature

Visual

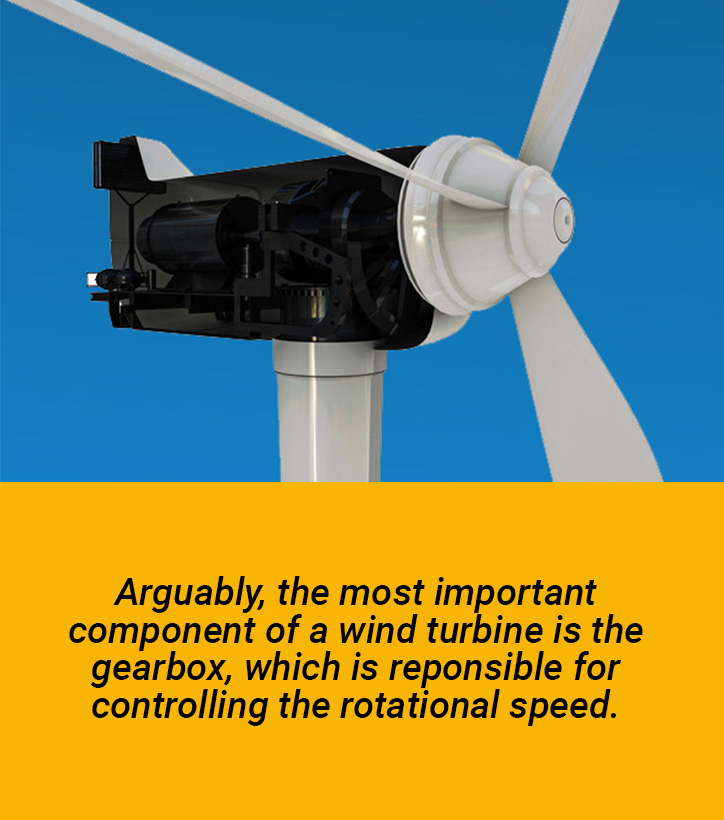

Arguably the most important component of a wind turbine is the gearbox, which is responsible for controlling the rotational speed. Any cracks or corrosion in the gearbox can lead to an accident that would be very dangerous and extremely costly.

THE PROBLEM

No one inspection type can provide a complete and accurate assessment of a wind turbine. Therefore, a combination of different inspections is essential to gain a thorough understanding of its condition. This is especially true when Denise had to inspect the gearbox and found the damaged bearing.

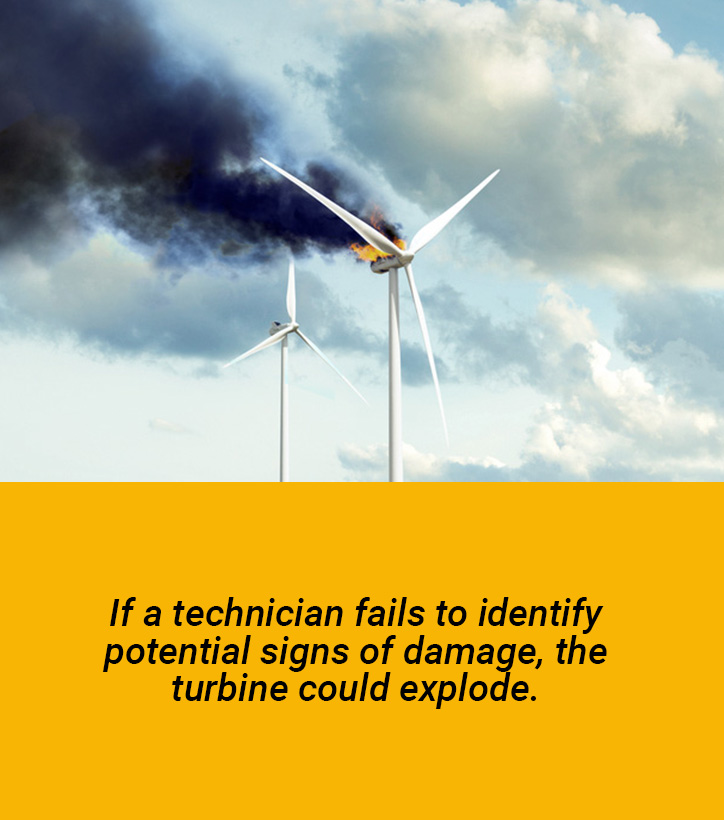

If a technician fails to identify potential signs of damage the turbine could explode. A turbine’s gearbox regulates the rotor speed to make sure the generator’s energy output meets the grid’s requirements.

Specifically, the most common cause for these explosions is a failure of the bearings in the gearbox. These system failures put future technician’s lives at risk and are extremely costly to fix.

THE ANSWER

When inspecting a gearbox, visual inspection is one of the best ways to determine its health. Wind turbine technicians need to be able to see inside the component and detect cracks, corrosion, buildup, and other signs of severe wear.

An Articulating Video Borescope from SPI is the perfect tool for the job because it can give a clear inside view of the gearbox as well as reach deeper parts of the component that a technician cannot possibly get to without taking it apart.

THE RECON SERIES

SPI Borescopes is proud to introduce The RECON Series of Articulating Video Borescopes. With over 6 years in development, The RECON is quite possibly the best borescope ever made. We asked the top engineers in Aviation, Manufacturing, Power-Gen, Oil & Gas, and several other industries what they wanted in the perfect borescope. We listened, and then we delivered.

FEATURES

Massive Ultra Clear 6″ Screen

Seamless 4-way 360° Power Glide Articulation

Interchangeable Probes & PackagesLEARN MORE