Aviation and Aerospace

ARTICULATING VIDEO BORESCOPES FOR AVIATION TECHNICIANS

Feet propped up on his desk, Dave reviews the day’s maintenance calendar while sipping his scalding cup of black coffee.

It’s only 7 am when he gets a call about an incoming commercial passenger plane inbound from Paris, France that’s in serious need of a speedy inspection. The schedule for this plane is already 3 hours behind so Dave has to move quickly to the dock where the plane will taxi to.

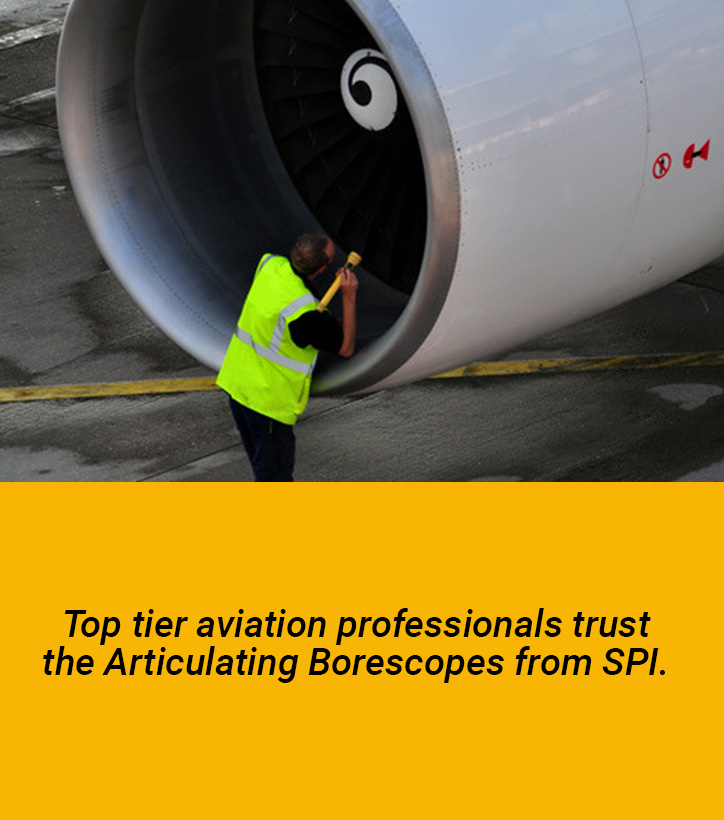

This inspection is a routine maintenance check, but time is not on Dave’s side. Immediately he begins to prepare for the plane that will be arriving in the next half hour. Before heading out he packs his toolbox with an Articulating Video Borescope which he trusts for fast, accurate inspections that ensure the continued safety of all passengers.

Taking one last swig of coffee, Dave leaves his office and is welcomed by the muggy summer air as he hurries to the plane’s dock, tools in hand and ready for the task ahead.

Right now as you read this there are 7000 planes actually in the air. Flying conditions aren’t always ideal so regular maintenance checks like the one mentioned above are incredibly important.

Every single day there are more than 10,000 aircrafts taking to the air with passengers and cargo in tow, which means no aircraft can take the risk of not being able to conduct thorough and comprehensive inspections. Maintenance engineers like Dave have to always be equipped with tools that get the job done right, because so many lives are on the line every single day.

THE INSPECTION

Nondestructive inspections are inspections that determine the airworthiness of aircraft components without destroying them.

These inspections are largely visual inspections.

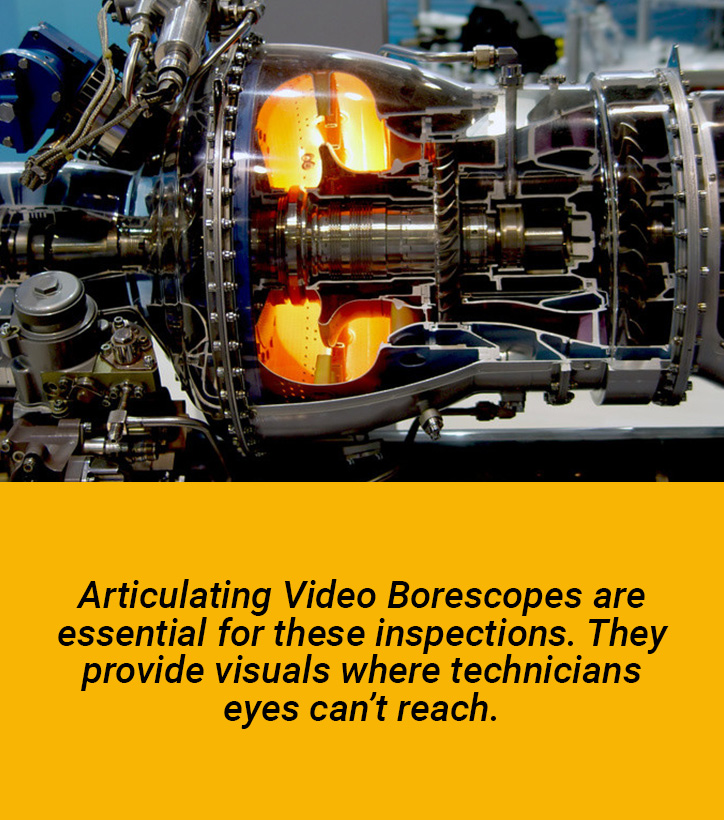

Some common components for these types of inspections include:

Combustion chamber

Reciprocating engine cylinder

Turbine blades

Articulating Video Borescopes are essential for these inspections. They provide visuals where the technician’s eyes can’t reach. Technicians have to be able to detect cracks, buildup, corrosion, damaged pistons, and more in order to successfully conduct a thorough inspection.

THE PROBLEM

Without eyes inside engine components, maintenance technicians are blind to what could be wrong with the aircraft engine.

This leaves them two options:

Option A: take the entire engine apart, wasting time and energy

or,

Option B: pray that nothing goes wrong.

This is why maintenance inspections have to be carried out completely, accurately, and punctually.

THE ANSWER

Top tier aviation professionals trust the Articulating Video Borescopes from SPI for their remote visual inspection needs because we provide the FEATURES you need, the QUALITY you desire, and a PRICE you can afford.

Non-destructive maintenance inspections help guarantee that aircraft’s components are still fully functional while allowing the plane to work inside their busy flight schedules with minimal delays.